Underpinning Solutions

Underpinning Solutions

Foundation settlement often occurs when soil expands during wet conditions, contracts during dry periods, or fails due to poor compaction.

Matthews Wall Anchor is a leader in commercial foundation underpinning throughout Pennsylvania and the surrounding region. Underpinning—also called piering—transfers the weight of a structure from unstable soils to deep foundation elements anchored in stronger, more suitable ground. This allows us to strengthen, support, and lift settling structures with minimal disruption to ongoing operations.

Underpinning is often needed when:

- The existing foundation is weak or experiencing settlement

- Soil conditions have changed due to drought, flooding, or poor compaction

- Nearby excavation or new construction affects surrounding soil

- Structural loads have increased or the building’s use has changed

- Early signs of settlement are occurring such as;

- Cracks in walls, floors, or ceilings

- Sticking windows or doors

- Bowing or leaning walls

- Sloping or uneven floors

Benefits of Foundation Underpinning

Underpinning stabilizes failing foundations, restores structural integrity, and makes buildings more accessible for inspections, renovations, and future improvements. Additional benefits include:

- Immediate structural load transfer—no waiting for concrete to cure

- Quiet, vibration-free hydraulic installation

- Minimal excavation or soil removal

- Installation from inside or outside the structure

- Adaptability for areas with tight or limited access

- Full load testing to verify performance and safety

We use industry-leading materials from Earth Contact Products (ECP)—the most trusted name in commercial underpinning systems. Our team provides free inspections to determine the cause of settlement and recommend the most effective underpinning approach.

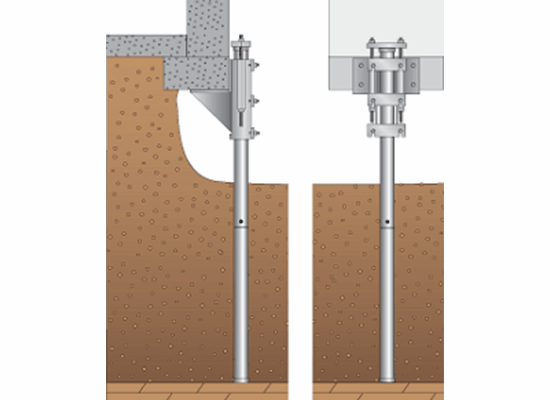

Steel Push Piers

Matthews Wall Anchor uses heavy-duty ECP steel push piers to stabilize and lift commercial structures. These resistance piers are driven deep into load-bearing soils using hydraulic equipment. A friction-reduction collar allows the pier to advance through the soil efficiently, and each pier is load tested during installation.

Advantages of steel push piers include:

- Quiet, clean, and vibration-free installation

- Fast results with immediate load transfer

- Reliable support that does not rely on skin friction

- Versatility for interior and exterior applications

- Proven performance for commercial and industrial structures

We provide full technical details on the 300, 350, and 400 ECP Series push piers used for our commercial projects.

Why Choose Matthews Wall Anchor

- Matthews Wall Anchor specializes in commercial underpinning using proven techniques and top-tier materials. Our process includes:

- Driving piers through unstable soils to reach solid bearing layers

- Load testing each pier for performance and safety

- Lifting the structure using hydraulic jacks for precise leveling

- Ensuring immediate stabilization after installation

Additional advantages:

- Installation inside or outside the footprint of the structure

- Minimal soil disturbance

- Portable hydraulic systems for tight areas

- Reliable bracket attachment to existing foundations

- Immediate structural support—no curing time required

Our decades of experience and industry-leading products allow us to deliver consistent, long-lasting results for commercial buildings of all sizes.

Matthews Structural Solutions uses augercast piles manufactured by Earth Contact Products (ECP), the very best foundation repair products in the industry today. These piling systems are ideal for commercial and industrial applications where reliability and performance matter. Please visit their website at www.earthcontactproducts.com for product information.

We know it is important to maintain proper quality control when installing augercast piles to avoid discontinuous concrete diameters over the length of the pile. That is why we use a recording system on our augercast pile projects to confirm drilling and grouting parameters during installation. Our structural contractors will help ensure that the project runs smoothly from start to finish and are also equipped to perform piling repair if necessary.

Request a Free Estimate

Get a free, no-obligation inspection from Matthews Wall Anchor—trusted specialists in foundation repair, waterproofing, and structural stability.